Top 9 Applications of AI-Based Quality Inspection in Manufacturing (2025–26)

In 2025–26, global manufacturing stands at an inflection point, where precision, productivity, and profitability converge through AI-based quality inspection systems. According to McKinsey, AI adoption in production can improve defect detection by up to 95%, increase throughput by 30–40%, and reduce inspection labor costs by 50–70%. Meanwhile, the Inspection Software Market is projected to grow from $11B in 2025 to $24.95B by 2032 (Fortune Business Insights).

Key Benefits of AI in Quality Control:

Enhanced Accuracy: AI systems can detect defects that are often imperceptible to the human eye, ensuring higher precision in quality assessments.

Increased Efficiency: Automated inspections reduce the time required for quality checks, leading to faster production cycles.

Scalability: AI solutions can be scaled across multiple production lines and facilities, maintaining consistent quality standards.

Cost Savings: By reducing waste, rework, and labor costs, AI-driven quality control systems offer significant financial benefits.

At ThirdEye Data, we’ve been at the forefront of this AI adoption, developing and deploying AI-powered quality inspection systems for diverse manufacturing clients across automotive, electronics, energy, consumer goods, and pharmaceuticals. Our approach combines deep domain understanding, custom AI engineering, and enterprise-grade data integration. We help manufacturers shift from reactive QC to proactive, predictive, and intelligent inspection ecosystems.

Let’s explore the top nine AI applications adding most business value in the process of quality inspection in manufacturing, and how they drive measurable business value.

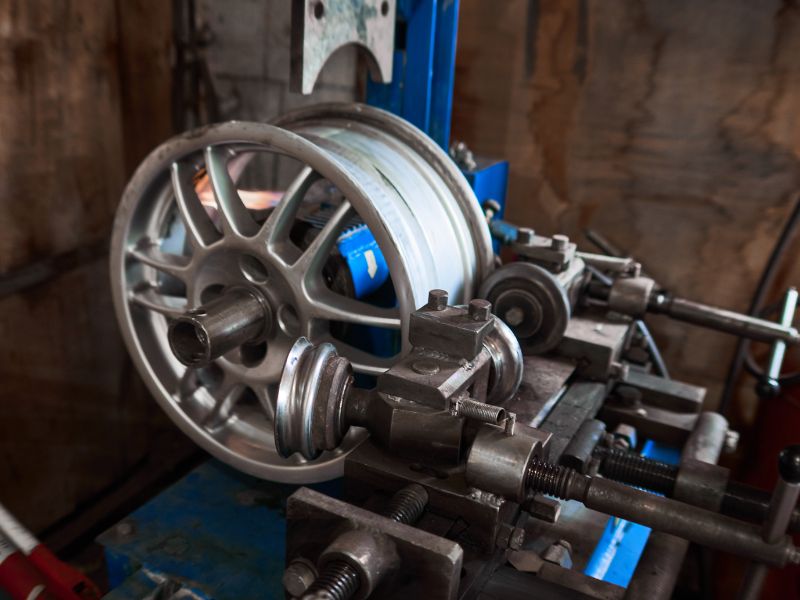

Dimensional Accuracy & Shape Deviation

In industries such as automotive and aerospace, maintaining precise dimensional accuracy is critical. Even minor deviations can lead to assembly issues, product failures, and increased costs.

Role of AI Systems for Ensuring Dimensional Accuracy & Detecting Shape Deviation:

AI-based quality control systems utilize 3D vision and point cloud analysis to compare manufactured parts against CAD models, identifying deviations in real time.

Recommended Solution Approaches:

Commercial Tools & Software: NVIDIA Metropolis, Cognex VisionPro

Open Source Technologies: OpenCV, PyTorch3D

Hybrid Approach: Combining commercial hardware with open-source software for customized solutions

How AI Solutions Work:

Capture 3D scans or images of the product

Preprocess the data to remove noise and align with CAD models

Use algorithms like Iterative Closest Point (ICP) to detect deviations

Provide feedback to the production line for immediate corrections

Datasets, Inputs, and Infrastructure:

Datasets: Annotated 3D models, historical defect data

Inputs: CAD files, 3D scans

Infrastructure: Edge computing devices (e.g., NVIDIA Jetson), high-resolution 3D cameras

Tools and Technology Stack:

Cameras: Basler, FLIR

Software: OpenCV, TensorFlow, PyTorch3D

Integration: ROS2, OPC-UA

Estimated Cost:

Development costs range from $70K to $100K, depending on the complexity and scale of the implementation.

Practical ROI and Business Impacts:

Defect Reduction: Up to 60%

Inspection Time: Reduced by 70%

Return on Investment: Achieved within 12–18 months

Insights and Tips:

Regular calibration of 3D scanners is essential to maintain accuracy.

Synthetic data generation can enhance model robustness.

Edge deployment ensures real-time processing and reduces latency.

Surface Quality & Texture Consistency

Surface defects such as scratches, dents, and discoloration can compromise product aesthetics and functionality, particularly in industries like electronics and consumer goods.

Role of AI Systems for Controlling Surface Quality & Texture Consistency:

AI systems employ convolutional neural networks (CNNs) to analyze surface textures, detecting anomalies that may indicate defects.

Recommended Solution Approaches:

Commercial Tools & Software: Cognex VisionPro, Keyence

Open Source Technologies: OpenCV, TensorFlow

Hybrid Approach: Utilizing commercial imaging hardware with custom AI models

How AI Solutions Work:

Capture high-resolution images of the product surface

Preprocess images to normalize lighting and enhance features

Apply CNNs to identify and classify surface anomalies

Trigger alerts or automatic rejection mechanisms

Datasets, Inputs, and Infrastructure:

Datasets: Annotated defect images, texture patterns

Inputs: RGB images, multispectral images

Infrastructure: High-resolution cameras, edge computing devices

Tools and Technology Stack:

Cameras: Basler, FLIR

Software: OpenCV, TensorFlow, Keras

Integration: PLCs, MES systems

Estimated Cost:

Implementation costs range from $60K to $90K, influenced by the complexity of the surface features and required resolution.

Practical ROI and Business Impacts:

Defect Detection Accuracy: Improved to 95%

Inspection Time: Reduced by 50%

Return on Investment: Realized within 6–12 months

Insights and Tips:

Consistent lighting conditions are crucial for accurate surface analysis.

Training models with diverse datasets improves generalization.

Integration with automated sorting systems enhances efficiency.

Color Uniformity & Finish

In industries like textiles and packaging, color consistency is vital for brand identity and consumer satisfaction. Variations can lead to product rejections and customer complaints.

Role of AI Systems to Detect Defects on Color Uniformity & Finish:

AI systems analyze color histograms and apply clustering algorithms to detect deviations from target color profiles.

Recommended Solution Approaches:

Commercial Tools & Software: X-Rite, Datacolor

Open Source Technologies: OpenCV, scikit-image

Hybrid Approach: Combining commercial color measurement devices with open-source software for analysis

How AI Solutions Work:

Capture images under controlled lighting conditions

Convert images to appropriate color spaces (e.g., Lab, HSV)

Apply clustering algorithms to identify color clusters

Compare with reference profiles to detect deviations

Datasets, Inputs, and Infrastructure:

Datasets: Color reference libraries, annotated images

Inputs: RGB images, spectral data

Infrastructure: Colorimeters, spectrophotometers, edge computing devices

Tools and Technology Stack:

Cameras: X-Rite, Basler

Software: OpenCV, scikit-learn, TensorFlow

Integration: MES systems, automated sorting mechanisms

Estimated Cost:

Development costs range from $50K to $80K, depending on the number of SKUs and required color accuracy.

Practical ROI and Business Impacts:

Color Mismatch Reduction: Achieved up to 70%

Inspection Time: Reduced by 60%

Return on Investment: Realized within 6–9 months

Insights and Tips:

Regular calibration of color measurement devices is essential.

Incorporating spectral imaging can enhance accuracy for reflective surfaces.

Batch-specific calibration improves model performance.

Component Presence & Placement Verification

Ensuring all components are present and correctly placed is crucial in industries like electronics and automotive. Missing or misaligned parts can lead to functional failures and safety issues.

Role of AI Systems for Confirming Component Presence & Placement Verification:

AI systems utilize object detection algorithms to verify the presence and correct placement of components in real time.

Recommended Solution Approaches:

Commercial Tools: Cognex In-Sight, Keyence

Open Source Technologies: OpenCV, YOLO, TensorFlow

Hybrid Approach: Combining commercial cameras with custom AI models for detection

How AI Solutions Work:

Capture images of the assembly line

Apply object detection algorithms to identify components

Verify placement and orientation against reference models

Trigger alerts or automatic rejection mechanisms

Datasets, Inputs, and Infrastructure:

Datasets: Annotated images of assemblies, CAD models

Inputs: RGB images, depth maps

Infrastructure: High-resolution cameras, edge computing devices

Tools and Technology Stack:

Cameras: Basler, FLIR

Software: OpenCV, YOLO, TensorFlow

Integration: PLCs, MES systems, robotic arms

Estimated Cost:

Implementation costs range from $60K to $100K, influenced by the complexity of the assemblies and required accuracy.

Practical ROI and Business Impacts:

Misassembly Reduction: Achieved up to 85%

Inspection Time: Reduced by 70%

Return on Investment: Realized within 12–18 months

Insights and Tips:

Training models on multiple orientations enhances detection accuracy.

Early integration into the assembly line prevents defects.

Regular updates to models are necessary to accommodate new components.

Assembly & Alignment Accuracy

In industries such as automotive, aerospace, electronics, and packaging, proper assembly and alignment of components are critical for product functionality, safety, and aesthetics. Misaligned parts can lead to operational failures, increased warranty claims, and customer dissatisfaction. AI-based systems ensure precise fit, alignment, and orientation, reducing errors and improving throughput.

Role of AI Systems for Assembly & Alignment Accuracy:

Detect gaps, misalignments, and incorrect orientation

Verify assembly against CAD models or reference images

Enable real-time feedback to operators or automated machinery

Recommended Solution Approaches:

Commercial Tools: Keyence, Cognex, Hexagon Metrology

Open Source Technologies: OpenCV, PyTorch, TensorFlow, PointNet for 3D point cloud analysis

Hybrid Approach: High-precision commercial cameras for acquisition + AI models trained on historical assembly data

How AI Solutions Work:

Capture images or 3D scans of assembled parts

Preprocess to normalize lighting, orientation, and remove noise

Apply pose estimation, geometric comparison, and edge detection algorithms

Highlight deviations or trigger automated corrections

Datasets, Inputs, and Infrastructure:

Datasets: CAD models, reference images of correctly assembled parts, historical defect data

Inputs: RGB images, depth maps, 3D point clouds

Infrastructure: Edge GPUs for real-time processing, synchronized cameras on assembly line

Tools & Technology Stack:

Cameras: FLIR, Basler, structured light 3D scanners

AI/ML: PyTorch, TensorFlow, OpenCV, 3D vision libraries

Integration: MES, PLCs, robotic actuators

Estimated Cost:

Development and deployment costs: $70K–$120K, depending on assembly complexity and required precision

Practical ROI and Business Impacts:

Defect Reduction: 50–80% reduction in mis-assembled units

Inspection Time: Reduced by 60–70%

Return on Investment: Typically start getting ROI in 12–18 months

Insights & Tips from Hands-on Experience:

Multi-angle imaging improves detection accuracy for complex assemblies

Real-time feedback integration with robotic arms reduces downtime

Synthetic 3D datasets can accelerate model training for rare or complex assembly errors

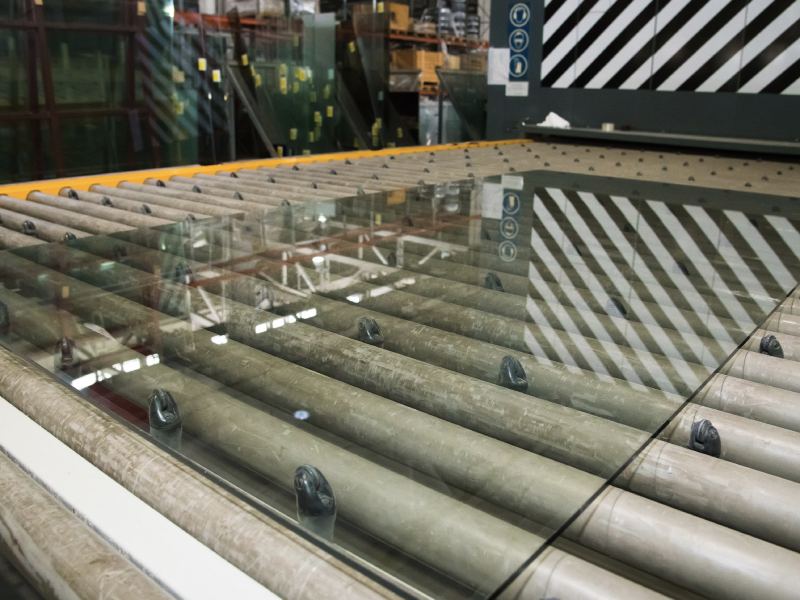

Contamination or Foreign Material Detection

Industries like food, pharmaceuticals, and semiconductors face serious risks from contamination. Undetected foreign particles can cause recalls, legal liabilities, and safety hazards. AI inspection systems ensure cleanliness and compliance, reducing the risk of defective or unsafe products reaching consumers.

Role of AI Systems for Contamination or Foreign Material Detection:

Detect dust, hair, oil, metal shards, or moisture

Leverage hyperspectral imaging and anomaly detection to spot contaminants invisible to the naked eye

Recommended Solution Approaches:

Commercial Tools: Cognex In-Sight 3D-L4000, Keyence

Open Source: OpenCV + CNN-based anomaly detection, TensorFlow

Hybrid Approach: Industrial cameras with custom-trained ML models for real-time detection

How AI Solutions Work:

Capture RGB, IR, or hyperspectral images of products on the production line

Apply anomaly detection models to identify unexpected patterns

Trigger real-time alerts to halt or divert affected products

Datasets, Inputs, and Infrastructure:

Datasets: Clean vs. contaminated images, historical contamination logs

Inputs: RGB, IR, hyperspectral images

Infrastructure: Edge GPUs, vibration-free mounts, cleanroom-compatible sensors

Tools & Technology Stack:

Cameras: Basler, FLIR, hyperspectral imaging systems

AI/ML: PyTorch, TensorFlow, autoencoder models for anomaly detection

Integration: MES, PLC, automated sorting/conveyor systems

Estimated Cost:

Usually, it costs around $80K–$120K depending on camera resolution and AI complexity

Practical ROI and Business Impacts:

Defective product reduction: 80–95%

Labor savings: 50–60%

Payback: 9–12 months

Insights & Tips:

Use multispectral imaging for transparent or reflective packaging

Augment datasets with synthetic contamination scenarios for rare defect detection

Regular sensor calibration ensures consistent detection

Pattern & Logo Validation

For packaging, branding, and traceability, accurate printing of logos, barcodes, QR codes, and expiration dates is critical. Misprints lead to regulatory issues, brand damage, and supply chain problems.

Role of AI Systems for Pattern & Logo Validation:

Validate printed text, logos, barcodes for clarity, position, and correctness

Use OCR and object detection to verify labels

Recommended Solution Approaches:

Commercial Tools & Software: Cognex VisionPro, Keyence

Open Source: Tesseract OCR, OpenCV, PyTorch

Hybrid Approach: Cameras with OCR models trained on enterprise label datasets

How AI Solutions Work:

Capture high-resolution images of labels/packages

Apply OCR and logo detection models to check accuracy

Trigger alerts for incorrect or missing information

Datasets, Inputs, and Infrastructure:

Datasets: Reference images of correct labels, historical misprints

Inputs: RGB images, high-resolution scans

Infrastructure: Edge GPUs, industrial cameras, line-synchronized lighting

Tools & Technology Stack:

Cameras: Basler, FLIR

AI/ML: Tesseract OCR, YOLOv8, OpenCV

Integration: MES, ERP, automated rejection systems

Estimated Cost:

The average cost for building such AI systems is $60K–$90K.

Practical ROI and Business Impacts:

Mislabel reduction: 90%+

Manual inspection costs: Reduced by 70%

Payback: Within 6–9 months

Insights & Tips:

Keep OCR models updated for new fonts and label designs

Controlled illumination avoids false positives

Combine label verification with real-time line speed monitoring

Real-Time Process Drift Monitoring

Manufacturing processes can gradually drift due to equipment wear, environmental changes, or calibration errors. Detecting these subtle deviations early prevents defects, scrap, and downtime.

Role of AI Systems for Real-Time Process Drift Monitoring:

Continuously analyze production line data and video streams

Detect early signs of misalignment, tool wear, or process drift

Recommended Solution Approaches:

Commercial Tools: Seeq, TrendMiner

Open Source: Python-based statistical monitoring, PyTorch anomaly detection

Hybrid Approach: Edge AI for video + cloud analytics for trend visualization

How AI Solutions Work:

Capture video streams or sensor data from production

Apply statistical models and machine learning for anomaly scoring

Trigger predictive maintenance alerts or adjustments

Datasets, Inputs, and Infrastructure:

Datasets: Historical production metrics, video of normal operations

Inputs: Video feeds, sensor data, vibration or temperature readings

Infrastructure: Edge GPUs, time-synchronized cameras, MES integration

Tools & Technology Stack:

Cameras: Basler, FLIR

AI/ML: LSTM models, autoencoders for anomaly detection

Integration: MES, predictive maintenance software

Estimated Cost:

Average cost is $80K–$120K depending on process complexity

Practical ROI and Business Impacts:

Defect reduction: Up to 40%

Maintenance downtime reduction: 30–50%

Payback: 12–15 months

Insights & Tips:

Combine sensor data with video for higher accuracy

Use rolling windows and trend analysis to avoid false positives

Integrate alerts with operator dashboards for immediate action

Operational Metrics & Production Line Feedback

Understanding real-time production performance is crucial for efficiency and proactive decision-making. AI-based inspection systems not only detect defects but also provide actionable operational insights.

Role of AI Systems for Analyzing Operational Metrics & Providing Production Line Feedback:

Monitor defect rates, throughput, and rejection trends

Trigger automated adjustments in production parameters

Enable closed-loop optimization for line speed, tool temperature, or pressure

Recommended Solution Approaches:

Commercial Tools: Siemens Opcenter, Rockwell Automation FactoryTalk

Open Source: Python dashboards, Grafana, Prometheus, ML-based alerting

Hybrid Approach: Edge AI for real-time metrics, cloud analytics for reporting

How AI Solutions Work:

Aggregate data from AI inspection models and production sensors

Compute KPIs and detect anomalies in real time

Trigger automated corrective actions or operator alerts

Datasets, Inputs, and Infrastructure:

Datasets: Production line historical data, defect logs

Inputs: Sensor readings, camera feeds, MES data

Infrastructure: Edge computing, cloud dashboards, integration with PLC/MES

Tools & Technology Stack:

AI/ML: TensorFlow, PyTorch, scikit-learn

Visualization: Power BI, Grafana, custom dashboards

Integration: MES, PLC, SCADA

Estimated Cost:

The estimated cost for a full-scale deployment comes around $100K–$150K for large scale manufacturers.

Practical ROI and Business Impacts:

Real-time adjustments reduced defect rates by 30–50%

Throughput increased by 20–35%

Return on investment within 12 months

Insights & Tips:

Ensure high-frequency data capture for accurate metrics

Visualize trends for actionable insights

Integrate AI feedback loops for continuous process optimization

Market Insights & Industry Trends

AI adoption in quality inspection is growing rapidly, with the market expected to reach $12.14B by 2030 (Knowledge Sourcing Intelligence)

McKinsey reports that AI can improve defect detection by up to 95%, reduce inspection labor by 50–70%, and increase throughput by 30–40% (McKinsey)

Industries Leading AI-based QC System Adoption: Automotive, Electronics, FMCG, Pharmaceuticals, Textiles, Packaging

ThirdEye Data’s Project References on Developing AI-based Quality Checking & Controlling Systems

Project References: AI-based Quality Checking & Controlling Systems

AI-based quality inspection is no longer a futuristic concept but a present-day reality transforming manufacturing operations. At ThirdEye Data, we have developed a prototype of AI-based quality checking system, available at our AI demo central. From reducing defect rates and improving throughput to enhancing product quality and ensuring regulatory compliance, the benefits are clear.

As the manufacturing industry continues to evolve, embracing AI-driven quality inspection systems will be crucial for staying competitive. By leveraging advanced technologies and real-time data analytics, manufacturers can achieve higher efficiency, lower costs, and improved product quality.

If you’re ready to embark on your AI journey, ThirdEye Data is here to guide you every step of the way. Our team of experts can help you implement tailored AI solutions that meet your specific needs and drive measurable business outcomes.