Explore 20+ AI Solution Prototypes at Our AI Demo Central |

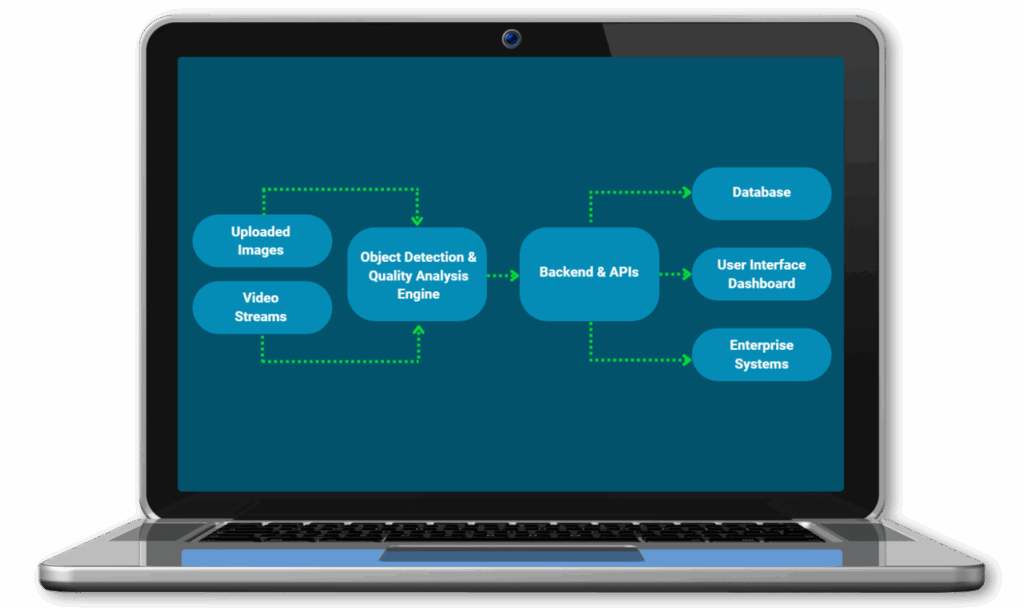

The Object Detection & Quality Analysis System is a computer vision-powered solution that detects and analyzes objects in real time from images or videos. Using advanced YOLO-based deep learning models, it identifies multiple objects simultaneously, highlights them with bounding boxes, and provides automated quality scores with confidence levels.

This solution is designed for industries where accuracy, quality, and real-time decision-making are critical, such as manufacturing, logistics, quality control, and surveillance. With high processing speed and scalability, it ensures operational efficiency and consistent product quality.

Manual inspection is slow, labor-intensive, and error-prone.

Detecting moving objects in real-time without automation is nearly impossible.

Lack of standardized quality metrics hampers performance tracking.

Traditional QC systems struggle with large-scale, real-time data streams.

Inefficiencies lead to higher costs and delayed deliveries.

Our system combines computer vision + YOLOv8 models to:

Detect and track multiple objects in real time for counting and quality checking purposes.

Generate bounding boxes with quality scores and confidence metrics.

Provide instant reports to standardize inspections.

Scale easily across production lines, logistics hubs, or surveillance systems.

Detect multiple items in a single frame with >90% accuracy.

Instant bounding boxes and feedback in under ~2.5 seconds per input.

Automated quality metrics for consistency and traceability.

Works with static images, live video, or recorded streams.

Easily deployable across multiple sites and industries.

Clear bounding box overlays with metrics for validation.

Faster throughput with automated inspections reduces bottlenecks.

Objective, standardized quality metrics improve compliance.

Automated package counting reduces shrinkage and delays.

Seamless API integrations enable centralized monitoring.

Transparent reporting with traceable quality scores.

Higher product consistency leads to stronger trust and satisfaction.

Experience how real-time vision AI transforms inspections and quality assurance.

Enterprises using this automated computer vision for object counting and inspections have reported:

70–80% reduction in manual inspection effort

Up to 90% accuracy in real-time detection and quality scoring

25–30% improvement in throughput across production lines

Our AI-driven solution combines real-time detection, counting, scoring, and seamless integration into enterprise workflows. Its scalability and adaptability across functions make it suitable for any data-intensive environment.

ThirdEye Data developed and deployed this computer vision solution to automate and optimize the manual process of counting finished components in a high-volume manufacturing environment. The AI-based system allows production floor staff to use a mobile application to capture images of bundled products, such as wires and connectors, which are then analyzed by AI algorithms to deliver accurate, real-time counts and quality metrics.

Q1. Can it integrate with my existing ERP/QC system?

Yes, the solution supports REST APIs for smooth integration with ERP, MES, and QC tools.

Q2. How accurate is the detection?

The system achieves over 90% accuracy in controlled environments and continues to improve with more training data.

Q3. Is it limited to manufacturing use cases?

No. It applies across logistics, retail, healthcare, and surveillance.

Q4. What infrastructure is required?

It can run both on cloud and on-premises, supporting standard GPUs for real-time inference.

Q5. Can the system handle large-scale video feeds?

Yes, it is designed for scalable processing of continuous video streams.