AI-powered Predictive Maintenance System

Downtime due to machinery and component failures can cost industries millions annually and impact operational efficiency and safety. The AI-powered Predictive Maintenance System uses machine learning to predict whether a component is likely to fail (“rogue”) or perform reliably, enabling proactive maintenance, reducing unplanned downtime, and improving overall equipment effectiveness. By leveraging historical component data, the system transforms maintenance from reactive to predictive, helping enterprises optimize costs and ensure reliability.

Business Challenges or Pain Points Addressed

Unplanned Downtime: Unexpected component failures disrupt production and reduce efficiency.

High Maintenance Costs: Reactive maintenance increases labor, repair, and replacement expenses.

Component Reliability Uncertainty: Without predictive insights, operators cannot differentiate between reliable and rogue components.

Safety Risks: Failing critical components can pose hazards to personnel and processes.

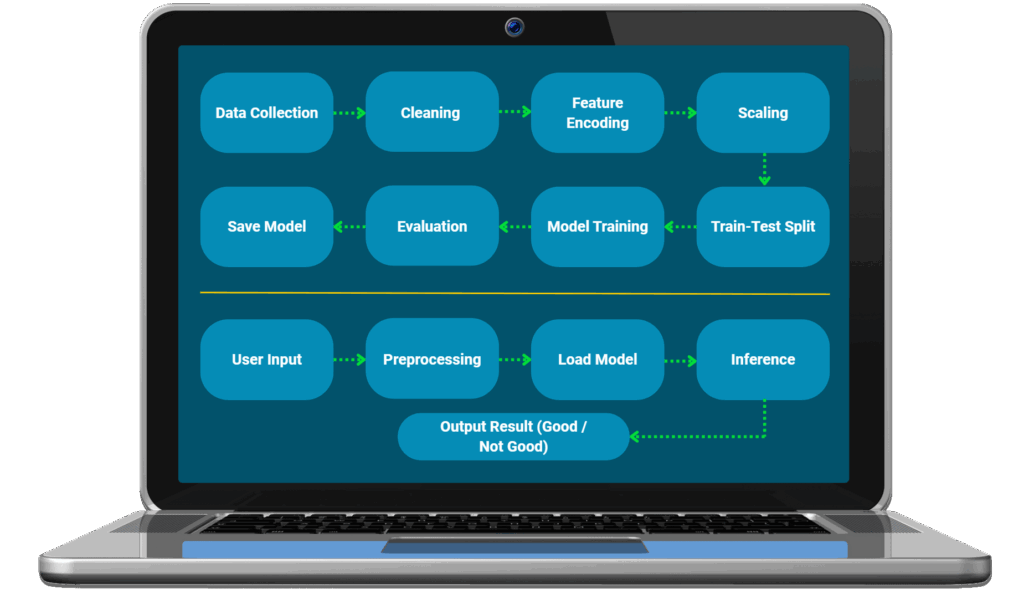

Our Solution Approach

The system applies supervised machine learning to historical component data to identify potential failures:

Data Preparation: Clean datasets, encode categorical features, normalize numerical variables.

Model Training: Feed-forward neural networks (TensorFlow/Keras) trained on labeled datasets to classify components as good or rogue.

Prediction & Inference: Preprocess new component data, perform inference using trained models, and generate binary classification.

Evaluation: Accuracy, precision, recall, and F1-score ensure the model meets high reliability standards.

Deployment: Models saved in .h5 or TensorFlow SavedModel format for seamless integration into operational workflows.

Technologies Used

Languages & Frameworks:Python, TensorFlow/Keras, Pandas, Scikit-learn

Preprocessing: Label encoding, Min-Max scaling

Visualization: Matplotlib, Seaborn

Model Deployment: .h5 / TensorFlow SavedModel format

Data Sources: Historical component datasets, operational metadata, maintenance logs

Core Features That Increase Factory Operation Efficiency

Predictive Component Classification

Automatically determines whether a component will likely fail or perform reliably using ML-based classification.

Data Preprocessing Pipeline

Handles encoding, normalization, and cleaning of structured component data for accurate predictions.

Real-Time Inference

Accepts new component inputs and provides instant binary classification results (Good / Not Good).

Model Training & Evaluation

Trains neural network models on historical data and validates performance with accuracy, precision, recall, and F1-score.

Deployment-Ready Models

Generates production-ready models (.h5 or SavedModel) for integration with enterprise maintenance systems.

Tangible Business Value Across Manufacturing Functions

Maintenance Teams

Reduce unplanned downtime by proactively identifying failing components and improving operational continuity.

Operations Managers

Optimize scheduling and maintenance cycles, saving labor and resource costs while maintaining uptime.

Engineering & Reliability Teams

Leverage accurate predictive insights to plan replacements and reduce failure-related process disruptions.

Finance & Operations Leadership

Lower repair and replacement expenses by reducing unnecessary maintenance and extending component lifespan.

Safety & Compliance Teams

Prevent critical failures and safety incidents by proactively monitoring high-risk components.

Maximize Uptime for Your Operations

See how our predictive maintenance system can prevent equipment failures, reduce costs, and maximize uptime for your operations.

Real-World Value Created Through This Automation

Predicts rogue components before failure, reducing unplanned downtime by up to 70%.

Enhances component reliability, supporting better scheduling and resource allocation.

Reduces maintenance and operational costs through proactive interventions.

Increases overall equipment effectiveness and safety in industrial operations.

What Makes This Solution Different

It surpasses the limitations of traditional reactive maintenance. This system applies supervised ML with structured preprocessing, training, and evaluation pipelines, delivering actionable, high-confidence predictions that can be directly integrated into maintenance workflows.

Developed a suite of predictive maintenance algorithms to analyze data from various sources to predict aircrafts’ component health and optimize maintenance schedules.

FAQs – Answering Common Business Asks

Q1: What data is required for predictions?

Historical component metadata, operational history, and maintenance logs.

Q2: How accurate is the prediction model?

High accuracy (over 85% accuracy rate), validated using precision, recall, F1-score, and real-world testing.

Q3: Can it predict failures for new types of components?

Yes, provided sufficient historical data exists to train the model effectively.

Q4: How are models deployed?

Models are saved in .h5 or TensorFlow SavedModel formats, ready for integration.

Q5: Is real-time inference supported?

Yes, the system processes new component inputs and outputs predictions instantly.